- Home

- /

- About Us

- /

- News

- /

- Product

- /

- Global Case

- /

- Friendship

- /

- Service

- /

- Contact Us

Concrete Mixer With Pump

Concrete Mixer With Pump

According to the actual construction requirement in the rural districts, small and medium towns, and various construction projects, our company researched and developed this new versatile equipment “concrete mixer with pump” combined with concrete mixing system and concrete delivering system. It is more convenient for the customers. The excellent performance is recognized in the several application fields, in the Concrete Industry as well as Industrial Plants (waste treatment, chemical industry, glass industry). Application industry: Concrete / Cement Products (Blocks, Pavers, Curbstones, Sleepers, Pipes, Rings), Precast Elements (Beams, Hollow Core, Safety Barriers, Wall Panels) ,Dam Construction, Road Paving, Industrial Floors, Architectural Precast, Waste Treatment, Foundries, Glass Industry, Mine Industry (muds treatment, backfilling),Soil Stabilization, Fertilizers.

PERFORMANCE

1. Suitable for the working area without power supply or lack of electricity;

2. Mixer and pump, combined in one machine, easy to be moved;

3. One worker to operate the mixing and pumping, save your labor cost;

4. PLC controlled, work stable, working life longer;

5. Loading, mixing, discharging and pumping, full hydraulic, full automatic;

6. Manual lubrication, separate water-cooled diesel engine;

7. Two usages of dragging support, could be used as charging platform;

8. Versatile, concrete mixer and concrete pump could work separately.

JBS40 (Eletric Type)

JBS40R (Diesel Type)

| Parts Name/Parameters | Parts Specification | ||||

| Models | JBT40 | JBT40R | HBT15-L1 | ||

| Power | Power Supply Model | Local Electricity 3P | Diesel Engine | Local Electricity 3P | |

| Electric Component | Siemens/Schneider/Omron | ||||

| Mixing System | Mixer | JZM450 Drum Mixer, 750L Charging Hopper, 450L Concrete Output Per Batch |

JS500 Twin Shafts Concrete Mixer, 800L Charging Hopper, 500L Concrete Output Per Batch | ||

| Mixing Motor | 5.5kW*2 | Hydraulic | 18.5kW | ||

| Hoist Motor | 5.5kW | Hydraulic | 5.5kW | ||

| Submersible Pump | 0.75kW | Hydraulic | 0.75kW | ||

| Max. Theoretical Mixing Output | 18-22m³/H | 25m³/H | |||

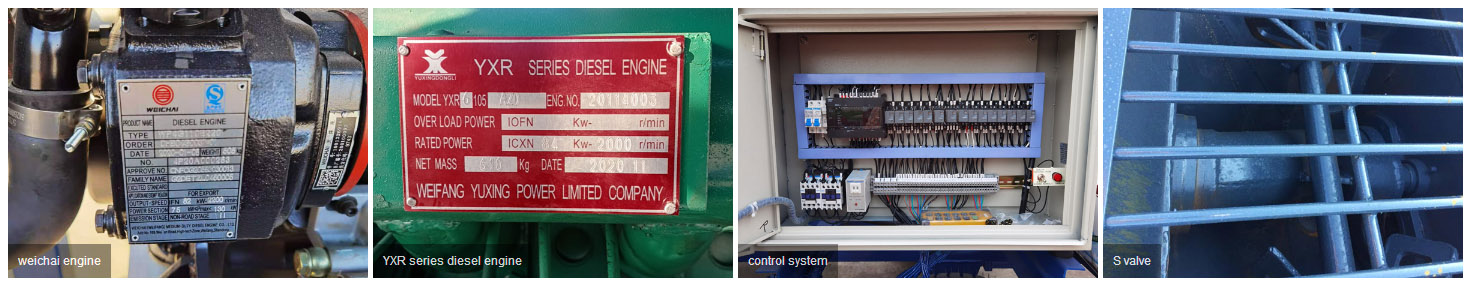

| Pumping System | Main Motor | 37KW | 72kW, Weichai Diesel Engine |

37KW | |

| Motor Rated Speed | 1480 RPM | 1800 RPM | 1480 RPM | ||

| Mian Hydraulic Oil Pump | KAWASAKI K3V112 | ||||

| Double Gear Pump | 25&16 | ||||

| Valves | Overflow And Directional Valves, OM, Italy Brand | ||||

| Main Oil Cylinder | Φ100*Φ70*1000mm | ||||

| Delivery Cylinder | Φ200*1000mm | ||||

| S Valve | Φ200mm | ||||

| Cutting Ring | Φ200mm | ||||

| Glass Wear Plate | Φ200mm | ||||

| Max. Theoretical Pumping Output | 40m³/H | ||||

| Outlet Pressure | 8Mpa | ||||

| Hydraulic System Type | Open Circuit | ||||

| Motor Rated Voltage | Customized | Diesel Engine | Customized | ||

| Max. Aggregate Size | Pebble:40mm Aggregate:30mm | ||||

| Delivery Height And Horizontal Distance | 70m/300m | ||||

| Hydraulic Oil Tank Volume | 200L | ||||

| Concrete Outlet Diameter | Φ180mm | ||||

| Hopper Capacity × Filling Height | 600*1400 (L*Mm) | ||||

| Machine Size(LxWxH) | 5100*2200*2450 Mm | ||||

| Total Weight | 5300kgs | 5600kgs | 7000kgs | ||

| Tyre Size | 700R16 | ||||

| Towing Speed | Max. 8km/H | ||||

1. Use double pumps, two-circuits open hydraulic system, oil circuit of the master pump and swing oil circuit of S distributing valve are independent, which makes the system easy, prolongs the lifespan of elements, the reliability is higher than before, and is convenient to judge and exclude the fault;

2. The reverse state is beneficial to eliminate fault of tube plugging and can stop functioning and wait for the materials for a short time. It is also good for prolonging the service life of the pump machine;

3. Use advanced S distributing valve, can automatically make up for wearing clearance and the seal performance is good;

4. Use wear-resistant alloy glasses board and float glass cutting, life service is long;

5. An automatic and intensive lubrication system ensures effective lubrication during the operation;

6. The remote control makes the operation safer and more convenient;

7. All the spare parts meet the national standard, and interchangeability is much better;

8. The cooling system uses a forced air cooling radiator device to ensure the working oil temperature, under 70 centigrade, and guarantee the main engine hydraulic system is in normal working condition.

Delivery to customer's site

Scan and follow our latest news

Scan and follow our latest news Contact:Mr.Wang

Mobile:+8613905357923

Email:13905357923@163.com

Address:26th Longmen east Road, Laiyang City,Shandong Province, China